| Product / Bag Making Machines / GS-323FS+DPT Fully Automatic High Speed Servo otor Control Die-cut Handle Patch Handle And Draw-Tape Handle Bags Making Machine |

|

|

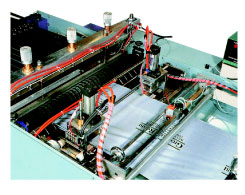

2. PHOTOCELL FOR PRINTED POSITION 2. PHOTOCELL FOR PRINTED POSITION3. REINFORCED SEALING This model of TGM uses the photocell for precise control of printed images to the side - welding. The additional stabilization of the side - welding in the area of the bottom gusseting by the special heating devices for the four layers of the film in order to get the reinforced sealings. |

4. SERVO MOTOR DRIVE SYSTEM (OPTION) 4. SERVO MOTOR DRIVE SYSTEM (OPTION)Servo motor drive system is available instead of the traditional clutch/brake,less maintenance and easy bag length setting are from one of the benefits of the servo motor drive system. |

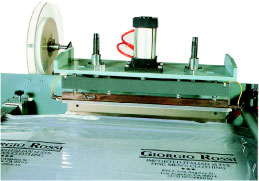

6. TOPS SEALING DEVICE (LIPS SEALING)

|

|

|

|

|

1. AUTO STACKER WITH CONVEYOR belts (OPTION)

1. AUTO STACKER WITH CONVEYOR belts (OPTION) 5. DRAW-TAPE GARBAGE BAGS MAKING DEVICE

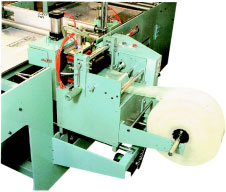

5. DRAW-TAPE GARBAGE BAGS MAKING DEVICE 7. PATCH HANDLE MAKING DEVICE

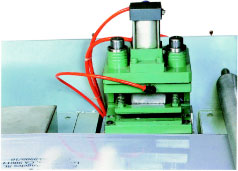

7. PATCH HANDLE MAKING DEVICE 8.HANDLE PUNCHING DEVICE

8.HANDLE PUNCHING DEVICE 9. TRIANGLE FOLDING DEVICE (OPTION)

9. TRIANGLE FOLDING DEVICE (OPTION)