Application range:

Material……………………………………….……: various compound films; laminated films; multilayers films

Roll folding………………………………….……..: max. width : 1200mm, max. diameter: 600mm

Auxiliary material………………………………….: max.width : 130mm, max. diameter: 350mm

Performance:

Bags making speed………………………..……...: 150 repeatings/min. (designed speed: approx.3000mm)

Bags making width………………………..………: max.600mm

Bags making length………………………………: 30-500mm (multiple conveying device can be adopted when the overlength is set), when the preset length is above 320mm, the system will change to multiple conveyances

Note……………………………………………….: the actual operation speed will reduce for the reason of differences of the bag length and materials.

Unwinding mode:

Main material……………………………………..: put the warp beam horizontally

Auxiliary material…………………………………: put the warp beam horizontally, with triangle folding device

Control…………………………………………….: with automatic tension device by swimming rollers, magnetic powder brake, displacement sensor

Feeding devices:

Material feeding……………………………………: synchronous drive of stepping motous (or servo motors)

Upper & lower sealing press………………………: driven by stepping motors (or servo motors)

Control functions:

Heating seal…………………………………………: speed of heat seal, duration of heat seal, proportion of heat seal, acceleration

Temperature…………………………………..……..: contact-free automatic control, CRT displaying

Counting…………………………………………….: presetting is available

Punching device…………………………………….: time can be preset, continous or interval punching mode is available

Working mode……………………………………….: printing, non-printing

Mode of multiple conveyances………………………: from twice to six times conveyances

Measurement for length………………………………: distance between color scales can be measured by photocell

Selectivity…………………………………………….: feeding without movement, upper & lower regulating trimmer can be selected

Alarm………………………………………………..: lost of printed point; lost of set temperature; warping alarm; servo motor alarm; tension alarm and auto-switch off the machine running

Electricity-comsumption:

Feeding synchronous drive of motors……………….: 1.00kw × 3 = 3.00kw

Upper & lower driving AC motors…………………..: 4.00kw × 1 =4.00kw

Warping traction motor……………………………….: 0.75kw × 1 =0.75kw

Side heat seal device………………………………….: 4.00kw × 5 = 20.00kw

Horizontal heat seal device……………………………: 4.00kw × 5 =20.00kw

Auxiliary material traction motor………………………: 0.20kw × 2 = 0.40kw

Zipper hert seal device…………………………………..: 4.00kw × 2 = 8.00kw

Control system and others……………………………….: 3.00kw

Total consumption……………………………………….: approx.60kw

Gas pressure………………………………………………: 0.60mpa (6kwf/cm?)

Cooling water……………………………………………...: approx.15L/min.

Gross weight of equipment………………………………..: 6tons

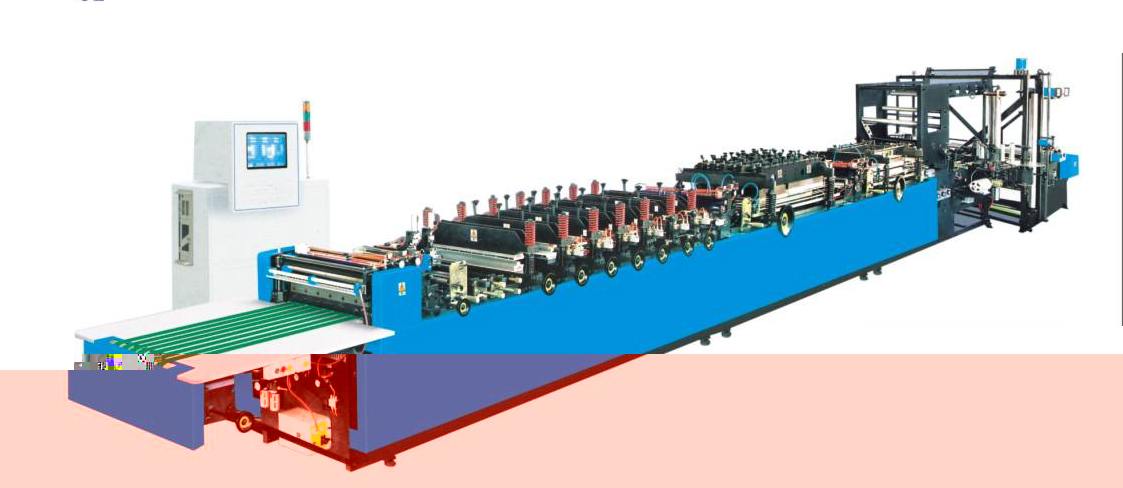

Dimensions (L X W X H )…………………………………: 1200×1900×1870mm

Control mode:

Adopts the industrial control equipment, domestic displayer.

Adopts PLC to control, touching screen displaying

Adopts multiple proximity switches system

|